Ensure Safe and Efficient Operations with Our Comprehensive Cable Precautions Guide

The most complete precautions for the use and storage of various cables

Chemical fiber cables cannot be used overloaded. The current actual tensile strength of the cable is determined based on factors such as the cable's service life, newness, wear and tear.

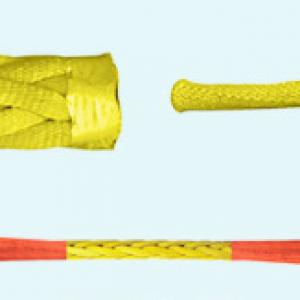

2. Chemical fiber cables are afraid of high temperatures and fire. They should avoid being exposed to the sun on the deck for a long time and keep away from fire sources. To avoid wear and tear, wear-resistant sheaths should be used where friction occurs when the cable passes through the fairlead.

3. Chemical fiber cables are afraid of being cut. When operating, prevent sharp objects from injuring the cables and avoid friction at sharp angles. Cable protective sleeves must be added to the cable eye rings and cable holes.

4. Polypropylene cables, polyester cables, and nylon cables have larger elongation rates. When untying the cable on the winch, you should gradually relax it to eliminate the elasticity. Once the cable breaks, it will rebound and easily injure people.

5. The mooring ropes should maintain a balanced force on each rope to prevent a certain rope from being damaged due to excessive elasticity, or even the risk of the rope breaking.

6 Chemical fiber ropes (especially towing ropes) look very good on the surface.

It is neither seriously damaged nor aged, but it has been subjected to a large tensile force for a long time. The cable's tensile strength has become fatigued, the cable has been stretched and thinned, the fiber molecular weight has been damaged, the stretchability is very poor, and the buffering is limited. It is suddenly subjected to a strong impact. There is always a risk of the cable breaking. This type of cable should be switched to a ship with a small load for use, and attention should be paid to gradually stressing the cable during use. Once the cable jumps and is accompanied by a rattling sound, it is a sign of a broken rope, and nearby personnel should pay special attention to it.

7 The nylon monofilament six-strand composite twisted cable rope has a right twist pitch when making the rope, which determines that the right twist must be added when the rope is put. Remember not to put the rope in the opposite direction (left twist)! The correct way to put the cable is as follows :

■When removing the outer packaging of the cable, do not place it in the opposite direction. Be sure to place it according to the arrow "one" pointing upwards on the outside of the factory package before removing it. After dismantling the outer packaging of the cable, place it smoothly in the direction of the arrow.

■Pull out the pipa head buckle of the cable and release it smoothly. Do not kink the cable during the rope release process, and then it can be loaded and wound on the ship.

■Follow the upward mark of the arrow "↓". If the arrow "↓" is placed downward in the opposite direction, the cable will become knotted and stranded, causing the cable to fail.

For normal use, the operator must pay attention.

8. The unused cables on the ship should be coiled and arranged neatly. The six-strand right-twisted cables should be coiled in a clockwise direction. The chemical fiber cables placed on the deck should be placed on the pallet to make the cables breathable and ventilated and not moldy. In order to prevent the cables from getting moldy, A canvas cover should be used when exposed to the sun.

9 Stop using or scrap the cable if the following conditions occur: the cable is obviously burnt or melted; the rope body has cuts, broken strands, kinks, and broken strands; one strand of the eight-strand cable is worn, and more than one strand of the 12-strand cable is worn; Polypropylene cables that have been placed on the deck for 2-3 years or more will appear powdery and fall off.

10. When storing cables, you should also pay attention to: the temperature of the storage place should not be too high, not exceeding 50-55°C. It cannot be stored with electrolytic copper and aluminum, and cannot be stored or in contact with chemical sulfuric acid. The storage place must be dry and ventilated.